Gas and oil pipeline flame arrester is widely used in petrochemical, gas, pharmaceutical, paper, food processing and other industrial fields. Specific usage scenarios include:

Oil, natural gas and other flammable and explosive gas transmission pipeline.

Flare system, oil and gas recovery system,Pipeline flame arresters for gas and oil heating furnace fuel gas pipe network, etc.

Coal mine gas discharge system, gas purification system, gas analysis system, etc.

There are various types and structures of flame arresters in natural gas and oil pipelines, but they are mainly composed of fire arrester elements, shells and accessories. Explosion proof pipeline flame arresters The flame arrester element is the core component of the flame arrester, and its material and structure directly affect the flame arrester effect. Common types of fire retardant elements include gravel, wire mesh and corrugated.

The working principle of gas and oil pipeline flame arrester is mainly based on heat transfer and wall effect:

Heat transfer: The flame arrester is designed with many small channels or pores, and when the flame passes through these channels, the flame is divided into several small flame flows. Due to the heat conduction effect of the channel wall, the temperature of the flame drops rapidly, and when it falls below the ignition point of the fuel, the flame is extinguished.

Wall effect: The collision probability between the free radicals generated during combustion and explosion and the channel wall increases, resulting in a decrease in the number of free radicals, thereby reducing the rate of combustion reaction. When the channel is narrow to a certain extent, the collision between the free radicals and the channel wall is dominant, the reaction cannot continue, and the flame is stopped.

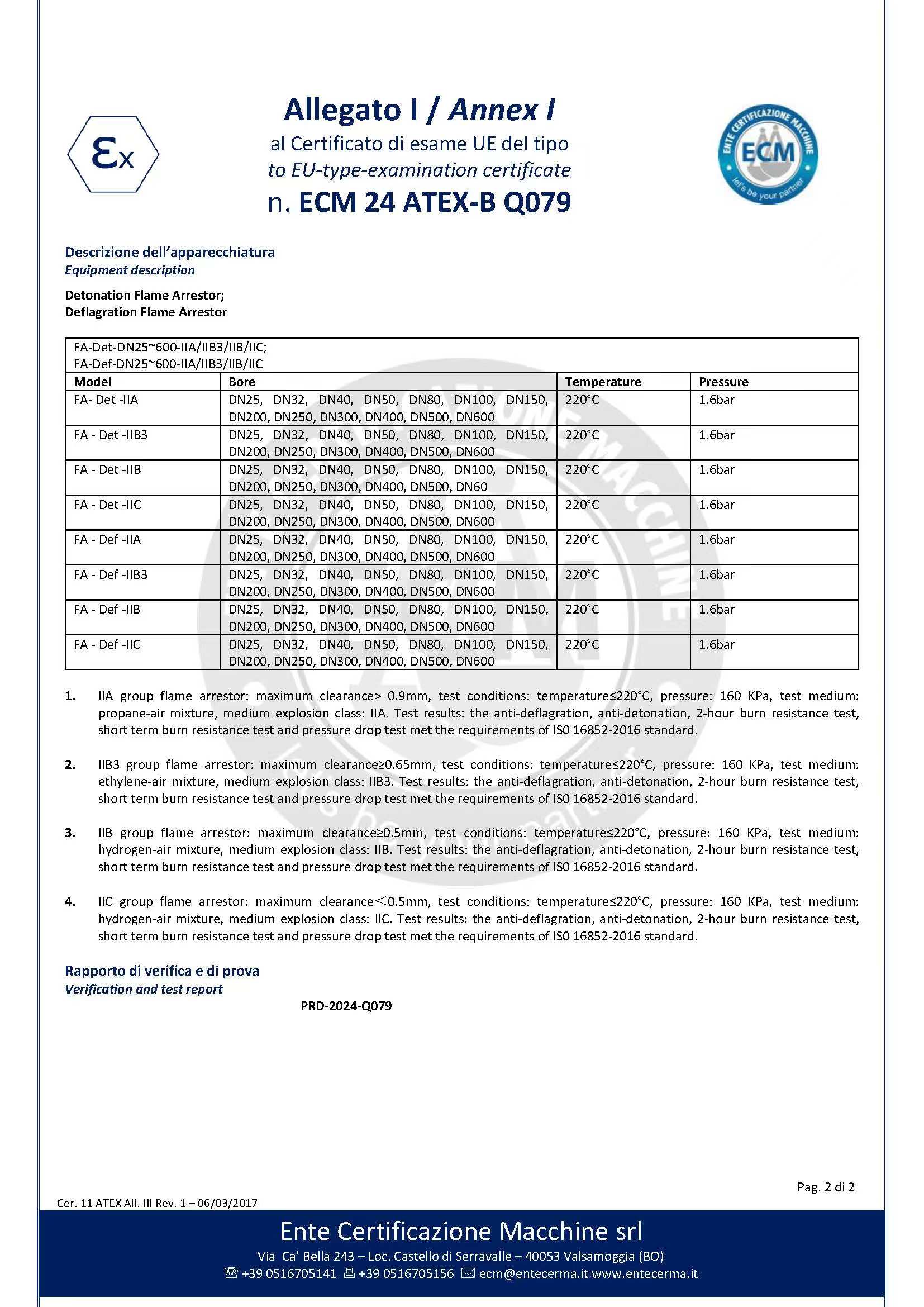

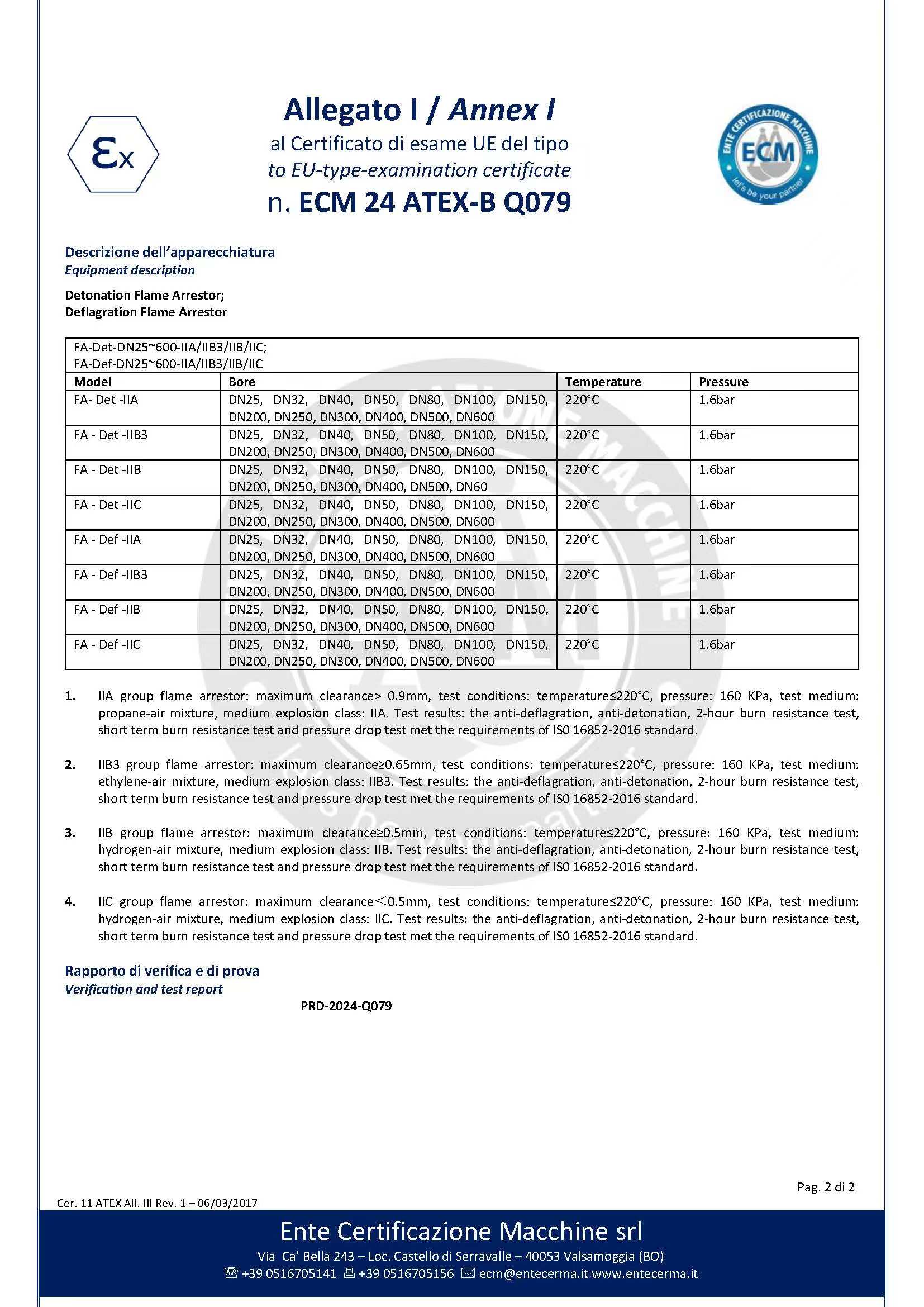

Eu test certificate for flame arrester: